Slotted/perforated pipes and tubes are common casing layer for pipe-core wire wrapped well screens. The perforated casing tube has round holes uniformly distributed for smooth flow of the liquid. It is actually a supporting pipe for sand control system in drilling oil or water wells. The metals are mostly stainless or mild steel.

How it Works: Perforated pipe or punched tubing is used as connection support. It links the wellbore and the producing formation through punched holes in the casing and the cement sheath that surrounds it.

|

| Perforated casing screen pipes, J55 or N80 |

The size and distribution of perforated hoses pose a direct impact on well productivity.

Features:

Available in J55 or N80. J55 and N80 have high strength and less potentiality of deformation.

Punched hoses are smooth and clear without burrs.

Easy installation.

Overall preservative treatment creates a dense protective layer over the surface of the pipe and improves corrosive resistance.

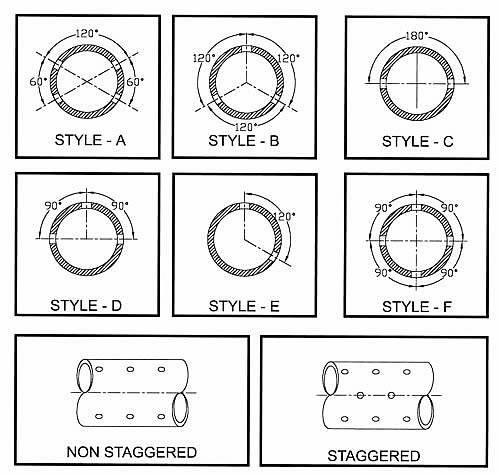

Six types of punched hoses are available for specific application.

Two types of hoses distribution are manufactured.

Punched Tube Hose types

Perforated Supporting Tube/Pipe Construction Illustration

Product parameters

Pipe Size (inch) |

Number of hoses (sq in./ft) |

Hole Diameter (inch) |

Open Area (sq in./ft) |

3/4 |

78 |

3/16 |

2.15 |

1 |

54 |

5/16 |

4.14 |

1-1/4 |

66 |

5/16 |

5.06 |

1-1/2 |

78 |

5/16 |

5.98 |

2-1/16 |

78 |

5/16 |

5.98 |

2-3/8 |

90 |

3/8 |

9.94 |

2-7/8 |

102 |

3/8 |

11.26 |

3-1/2 |

126 |

3/8 |

13.91 |

4 |

138 |

3/8 |

15.24 |

4-1/2 |

150 |

3/8 |

16.56 |

5 |

162 |

3/8 |

17.88 |

5-1/2 |

174 |

3/8 |

19.21 |

6-5/8 |

186 |

3/8 |

20.53 |

7 |

222 |

3/8 |

24.51 |

9-5/8 |

294 |

3/8 |

32.46 |

Galvanized Steel Perforated Tubing, Slotted with Round Holes