Carbon mild steel perforated metal pipes/tubes contain varying hole patterns of different sizes and shapes created by punching presses. Types of hole patterns include round, square, rectangular, scale, hexagonal and so on. Perforated steel tubing has the features of corrosion resistance, alkali resistance, accurate hole size and wide range of open area percentages.

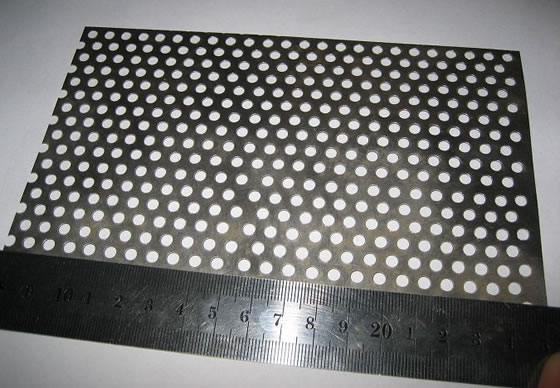

Perforated steel sheet for making of pipes or tubes: 1mm thickness, 4mm hole diameter, 7mm distance between holes, triaged 60 degree, 20mm free all side.

Perforated black steel Q235 applied for processing of tubing: 1.5mm thickness, 4mm hole diameter, 7mm distance between holes, triaged 60 degree,20mm free all side

This type of perforated tubing is made of high quality low carbon plain steel sheet after being perforated on the digital control perforated machines. It you don't see what you are looking for, we can custom punch many patterns.

| GAUGE | HOLES | CENTERS | OPEN AREA % |

| 26 | .020" | .043" | 20% |

| 26 | .027" | .050" STRAIGHT | 23% |

| 22 | 1/32" | 1/16" | 22% |

| 22-18 | 3/64" | 3/32" | 23% |

| 24 | .050" | .066" STRAIGHT | 45% |

| 22-18 | 1/16" | 3/32" | 45% |

| 16 | 1/16" | 7/64" | 30% |

| 20-16 | 1/16" | 1/8" | 23% |

| 20-14 | 5/64" | 1/8" | 36% |

| 20-14 | 3/32" | 5/32" | 33% |

| 24 | 3/32" | 3/16" | 23% |

| 18 | .117" | 5/32" | 51% |

| 22,18-14,11 | 1/8" | 3/16" | 40% |

| 12 | 1/8" | 7/32" | 29% |

| 18 | 9/64" | 3/16" | 51% |

| 20-16 | 5/32" | 3/16" | 63% |

| 20,10 | 5/32" | 1/4" | 36% |

| 22,18,16 | 3/16" | 7/32" | 67% |

| 24-14 | 3/16" | 1/4" | 51% |

| 18-3/16"PL | 3/16" | 5/16" | 33% |

| 22 | 1/4" | HEX | 79% |

| 22-16 | 1/4" | 5/16" | 58% |

| 20-1/4"PL | 1/4" | 3/8" | 40% |

| 16 | 1/4" | 3/8" STRAIGHT | 35% |

| 18 | 1/4" | 1/2"STRAIGHT | 23% |

| 18-14,10,3/16"1/4"PL | 5/16" | 7/16" | 50% |

| 16-1/4"PL | 3/8" | 9/16" | 40% |

| 20-14,10-1/4"PL | 1/2" | 11/16" | 48% |

| 10-1/4"PL | 5/8" | 7/8" | 46% |

| 16,11,3/16",1/4"PL | 3/4" | 1" | 51% |

| 10-1/4"PL | 1" | 1-3/8" | 48% |

| 3/16",1/4"PL | 1-1/4" | 1-5/8" | 54% |

| 10-1/4"PL | 1-1/2" | 2" | 51% |

| 10-1/4"PL | 2" | 2-1/2" | 58% |

| 10,3/16"PL | 2-1/2" | 3" | 63% |

| 10,1/4"PL | 3" | 3-1/2" | 67% |

| 10 | 3-1/2" | 4" | 70% |

| 10 | 4" | 4-1/2" | 72% |

Carbon Steel Materials Applied for Perforated Tubes Manufacturing:

Stainless Steel, unlike carbon steel, is corrosion resistant. It contains chromium which, when exposed to oxygen, creates an invisible protective film. Stainless steel types are classified into three different groups based on their ability to be hardened. Austenitic stainless steels, which can be hardened by cold working, meet a wide range of design criteria. They are essentially non-magnetic, although they may become slightly magnetic due to cold working.

Because carbon steel is susceptible to corrosion, it is typically used in either unexposed applications or protected with a coating. Coatings such as paint and powder are applied after perforating and completely protect the material. Zinc based coated metals (i.e. Galvanized, Galvannealed, etc.) on the other hand, are produced and supplied as such from the mill and may not completely protect the material where its carbon core is exposed during the perforating process.

Commonly Perforated Carbon Steel Types

Commercial Steel (HR, CR, GALV) A low cost steel that has good drawing, forming, and welding qualities, moderate strength, but is subject to strains, fluting, and breaks due to aging. To reduce the affects caused by aging, Drawing Steel is recommended.

Drawing Steel (HR, CR)

A steel with a greater degree of ductility and uniformity of properties than Commercial Steel providing improved performance during manufacturing. This type is recommended for use when stretcher strains or fluting during fabrication are objectionable and/or consistency of performance is important.

Forming Steel (GALV)

A steel with lower strength and higher elongation than Commercial Steel. Recommended when stresses from forming either crack or weaken Commercial Steel

| Hot Rolled Steel (Pickled and Oiled)Cold Rolled Steel Electro Galv. Steel | Hot Dipped Galvanized Steel† Aluminized Steel‡ |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gauge | Mean of Gauge | Min. of Gauge | Max. of Gauge | Min. of Gauge | Max. of Gauge | Lbs. per Sq. Ft. | Mean of Gauge | Min. of Gauge | Max. of Guage | Lbs. per Sq. Ft.† | Lbs. per Sq. Ft.‡ |

| 7 | .1793 | .1713 | .1873 | .1713 | .1873 | 7.500 | - | - | - | - | - |

| 8 | .1644 | .1564 | .1724 | 1564 | .1724 | 6.875 | .1681 | .1591 | .1771 | 7.031 | 6.934 |

| 9 | .1495 | .1415 | .1575 | .1415 | .1575 | 6.250 | .1532 | .1442 | .1622 | 6.406 | 6.319 |

| 10 | .1345 | .1265 | .1425 | .1285 | .1405 | 5.625 | .1382 | .1292 | .1472 | 5.781 | 5.701 |

| 11 | .1196 | .1116 | .1276 | .1136 | .1256 | 5.000 | .1233 | .1143 | .1323 | 5.156 | 5.086 |

| 12 | .1046 | .0966 | .1126 | .0986 | .1106 | 4.375 | .1084 | .0994 | .1174 | 4.531 | 4.471 |

| 13 | .0897 | .0827 | .0967 | .0847 | .0947 | 3.750 | .0934 | .0854 | .1014 | 3.906 | 3.853 |

| 14 | .0747 | .0677 | .0817 | .0697 | .0797 | 3.125 | .0785 | .0705 | .0865 | 3.281 | 3.238 |

| 15 | .0673 | .0613 | .0733 | .0623 | .0723 | 2.813 | .0710 | .0650 | .0770 | 2.969 | 2.929 |

| 16 | .0598 | .0538 | .0658 | .0548 | .0648 | 2.500 | .0635 | .0575 | .0695 | 2.656 | 2.613 |

| 17 | .0538 | .0478 | .0598 | .0498 | .0578 | 2.250 | .0575 | .0525 | .0625 | 2.406 | 2.363 |

| 18 | .0478 | .0428 | .0528 | .0438 | .0518 | 2.000 | .0516 | .0466 | .0566 | 2.156 | 2.113 |

| 19 | .0418 | - | - | .0378 | .0458 | 1.750 | .0456 | .0406 | .0506 | 1.906 | 1.863 |

| 20 | .0359 | - | - | .0329 | .0389 | 1.500 | .0396 | .0356 | .0436 | 1.656 | 1.613 |

| 21 | .0329 | - | - | .0299 | .0359 | 1.375 | .0366 | .0326 | .0406 | 1.531 | 1.488 |

| 22 | .0299 | - | - | .0269 | .0329 | 1.250 | .0336 | .0296 | .0376 | 1.406 | 1.363 |

| 23 | .0269 | - | - | .0239 | .0299 | 1.125 | .0306 | .0266 | .0346 | 1.281 | 1.262 |

| 24 | .0239 | - | - | .0209 | .0269 | 1.000 | .0276 | .0236 | .0316 | 1.156 | 1.113 |

| 25 | .0209 | - | - | .0179 | .0239 | .875 | .0247 | .0207 | .0287 | 1.031 | 1.019 |

| 26 | .0179 | .- | - | .0159 | .0199 | .750 | .0217 | .0187 | .0247 | .906 | .863 |

| 27 | .0164 | - | - | .0144 | .0184 | .688 | .0202 | .0172 | .0232 | .844 | .833 |

| 28 | .0149 | - | - | .0129 | .0169 | .625 | .0187 | .0157 | .0217 | .781 | .771 |

| 29 | - | - | - | - | - | - | .0172 | .0142 | .0202 | .719 | .709 |

| 30 | - | - | - | - | - | - | .0157 | .0127 | .0187 | .656 | .648 |